Rebecca Speare-Cole

Dec 23, 2025

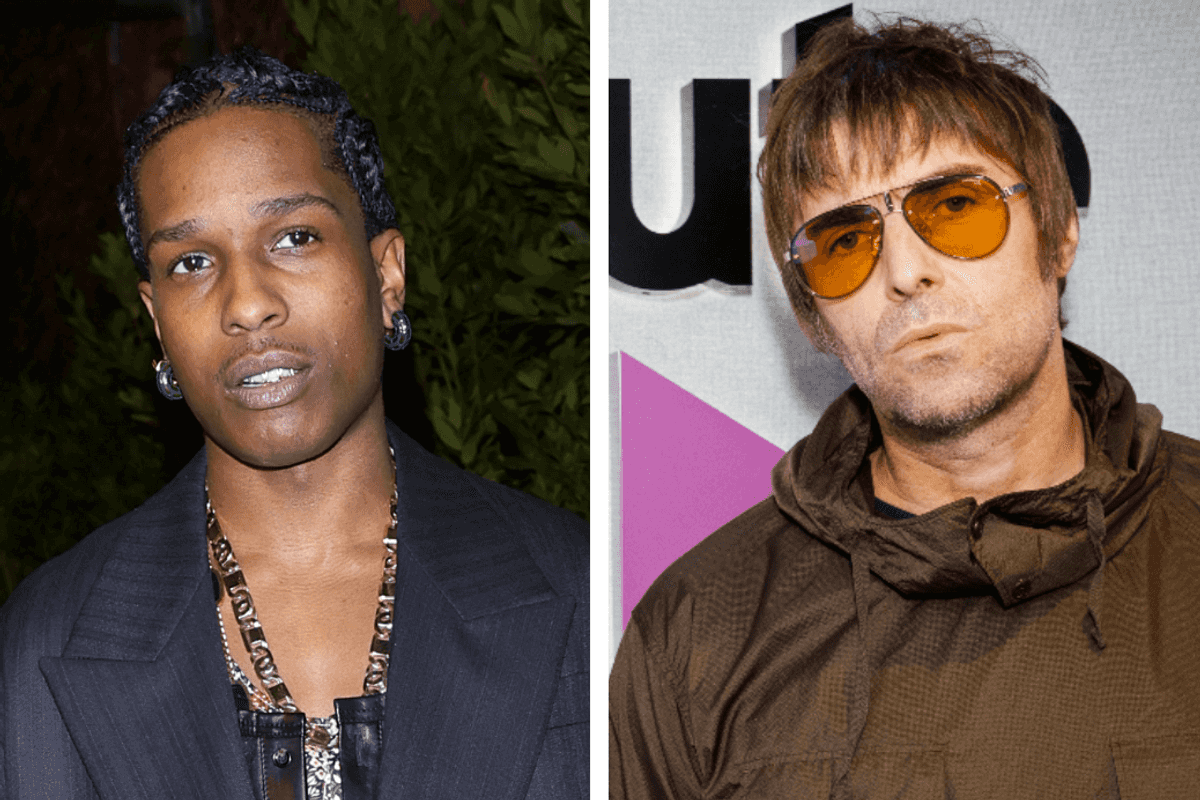

Workers on the Rirara Tea Estate in Kenya (Compact Syngas Solutions/PA)

A UK-backed initiative is working with farmers in Kenya to turn tea waste into clean energy and fertiliser.

The so-called “Green Tea” project aims to support producers in the east African nation, which supplies around half of the tea drunk in Britain.

Most of this is produced by more than 600,000 smallholder farmers, who have seen their yields reduced and livelihoods threatened by increasingly volatile climate conditions, which in turn has driven up prices for UK consumers.

Grace Njeri Koinange, a farmer who has been growing tea on her farm near the town of Limuru just north of the capital Nairobi for more than 40 years, told the Press Association: “The weather in the locality has changed a lot… particularly this year.

“We haven’t had much rain – it was very scant. This has changed the growing of the tea, so the production has really reduced in the last three years.”

Ms Njeri Koinange was among the first to take part in the UK-funded Green Tea project.

The early stages of the initiative involved artisanal biochar – a carbon-rich material produced by heating organic materials like tea prunings, wood offcuts and leaves – being applied on her farm as fertiliser to boost soil health and improve tea flavour.

“We found it was very good,” Ms Njeri Koinange said, adding that the section where the fertiliser was applied produced far more tea than other areas of the farm.

It comes as farmers like Ms Njeri Koinange face ever-tightening margins, as climate impacts and the low prices they are paid for their tea make it increasingly difficult to make a profit, or even meet the cost of labour.

“Particularly this year, we have had very low payment from the tea,” she said.

“We have struggled to make a profit because (the price) is not good enough.

“It is not comfortable and we have to struggle to keep going.”

Biochar is being touted as a potential solution to support Kenyan tea production, cut costs and boost sustainability but beyond the early stages of the project, Ms Njeri Koinange said she has yet to use it again as biochar is too expensive.

The hope is for their local tea factory to start producing industrial biochar once it obtains its own machinery.

“If you had the right machinery, it would be easier,” Ms Njeri Koinange said.

“It would definitely benefit the production of tea on the farm and we would be very excited to have it.”

As part of the Green Tea project, Browns Plantation in the northeastern town of Kericho is currently hosting a pilot of the technology developed by North Wales-based company Compact Syngas Solutions.

The machinery can turn leftover leaves and trimmings into synthesis gas, or syngas, which is widely considered a form of green energy because it releases fewer carbon emissions than other alternatives, while simultaneously producing biochar.

Tea factories often burn wood grown on the nearby farms to generate energy needed for drying out tea leaves, which can be labour-intensive and produce high levels of carbon.

The Compact Syngas Solutions system aims to support farming and factory complexes such as Browns to generate power, reduce emissions and decrease energy costs.

Paul Willacy, the firm’s chief executive, said the pilot has provided workers with four more months of employment as they gather the tea prunings used to create the power, and has helped factories to reduce their environmental impact.

“There’s a lot that goes into (tea production) behind the scenes that makes it very unsustainable,” he said.

In light of the success of the pilot, Mr Willacy said the technology could support more farmers in the Kenyan tea industry as well as other industries across the world.

“The rollout just in Kenya on the tea sector could be enough to keep us busy for several years, but it does certainly go beyond that,” he said.

“There are 100 plus tea factories in Kenya, so this could be very repeatable after this first pilot project, but it also makes you realise that, moving forward, there are lots of different countries, lots of industries, with very similar problems.”

The company first secured funding from Innovate UK’s energy catalyst programme, which allowed the firm to develop the system, with the Kenya pilot then supported by funding from the UN Industrial Development Organisation.

“Having something that’s in-country funded in this way de-risked it for everybody,” he said.

“Following on from that, future projects will all be privately funded because we’ve proven it, technically and economically – the viability of it.

“We’ve already got people who lined up who could potentially fund future projects. The opportunity is really big.”

On potentially helping to improve livelihoods in Kenya, he said: “That’s a fantastic thing for us.

“It’s one thing to be in the renewable sector, but actually to make a difference to people’s lives is incredible really.”

But Mr Willacy also said it will support British tea brands to become more sustainable across their entire supply chain.

“All the brands that we know and love and we see in the high streets – they’ve got a duty of care to become more sustainable.

“And this goes right away from the people who are selling it in the supermarkets right the way through to the people picking the tea leaves in the first place in the production.”

It comes as UK climate finance has helped to protect 137 million people from climate impacts since 2011, according to official figures released last month.

Development minister Baroness Jenny Chapman said: “If it was not for our support, a large proportion of those people would end up displaced from their homes, searching for a more secure existence elsewhere, exacerbating the severe problems we are already seeing across the world from conflict, food shortages and mass migration.

“That is why it is in everyone’s interests to invest in climate resilience and adaptation, and British businesses are central to that effort.”

Top 100

The Conversation (0)